You have several shops and unlike your colleagues with one shop, your business faces multiple challenges, including:

- Quality and consistency of bread in each of your shops

- Management of bread shortages and limitation of unsold products in each shop

- Staff management, recruitment of qualified personnel for each shop

- Management of raw material consumption

- Management of the traceability of raw materials and bread

- Optimisation of logistics, delivery between each shop (raw materials, products, etc.)

- Optimisation of your development (search for locations, profitability...)

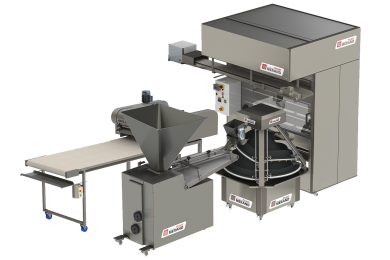

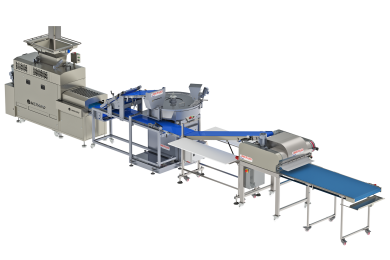

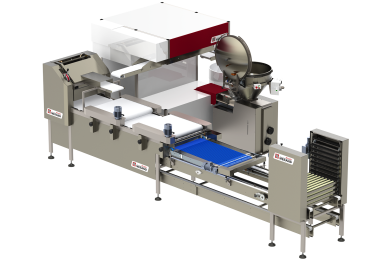

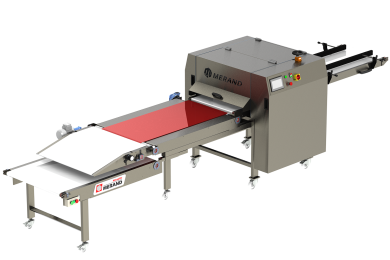

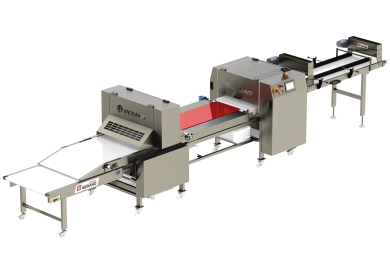

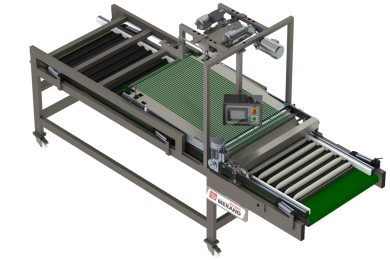

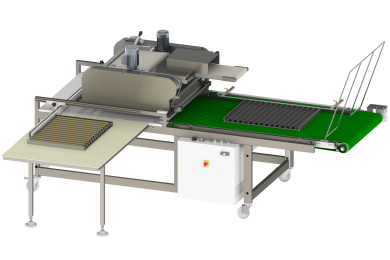

Even if the production in each shop according to the "classic method" (kneading, dividing, relaxing, shaping, fermentation in controlled growth, baking) remains, for the moment, the most widespread, it represents a great number of disadvantages. The solution for the future is in a centralised production for a part of the products. Each shop will be equipped to work with blocks of dough in slow motion. This has the advantage of making it easier to bake bread throughout the day, in order to limit the number of shortages during the day. Given the ease of implementation, without qualified personnel, this solution will allow the shop staff to divide and form the loaves as and when required by each shop. This will greatly reduce the number of unsold items at the end of the day.