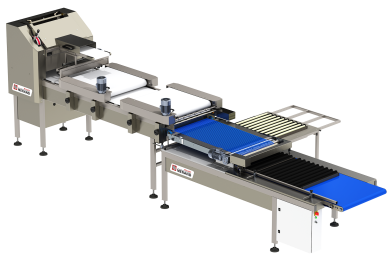

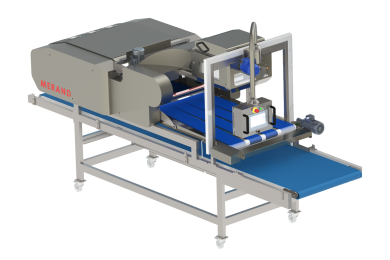

Moulding happens in 3 distinct steps, all of which are all very important:

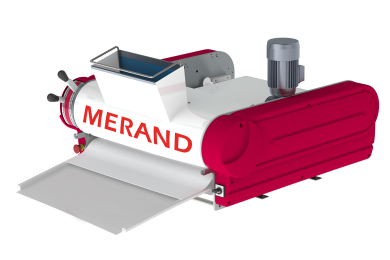

- A nice curly shape (so that the flat shape curls up well) thanks to a heavy belt or a chainmail belt.

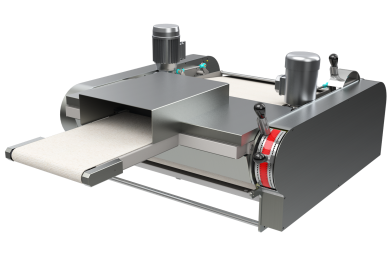

- Final elongation to get the elongation, laminations and the desired aspect of the baguette or breads.

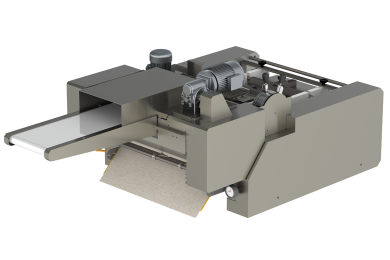

- The final stretching to obtain the desired length and appearance of the baguette or bread.