Semi-industrial and industrial bakeries have to manage high production volumes while offering a wide range of quality breads to their increasingly demanding customers. Production managers have to deal with high turnover, not always highly qualified staff and high production peaks at certain times of the year. Due to increased competition, your company has to face multiple challenges, including:

- Quality and regularity of bread

- Management of bread shortages and limitation of unsold products

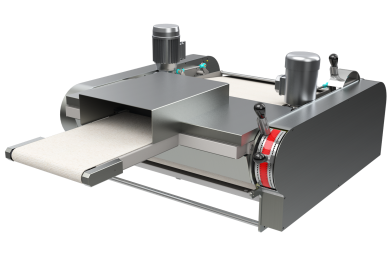

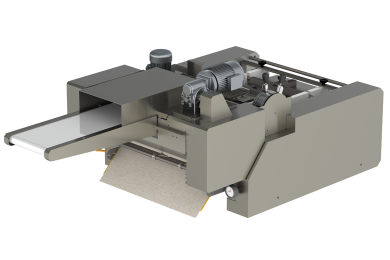

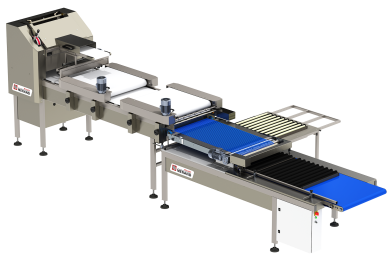

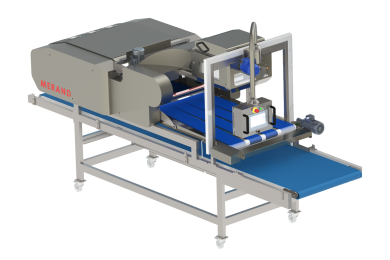

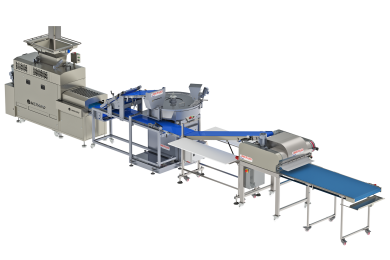

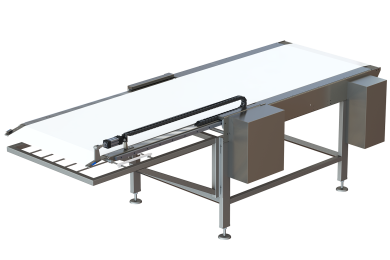

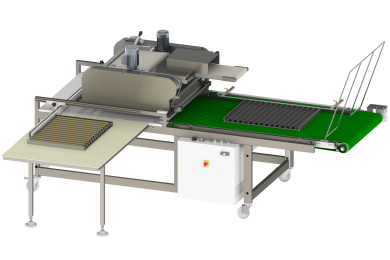

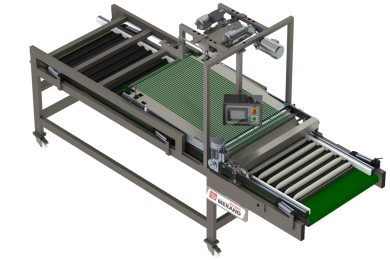

- Need for reliable, robust equipment, mechanically dimensioned to accept production volumes and rates

- Need for equipment that is easy to clean and use

- Labour and time management, recruitment and training of qualified personnel

- Safety at work, respect for employees' working conditions, reduction of MSD (Musculoskeletal Disorders)

- Management and traceability of raw materials

- Optimisation of your development (cost reduction, profitability, etc.)

- Compliance with production standards, available surface area, cleanliness of premises

As a specialist in the mechanisation of dough, MERAND is constantly working, in particular with its R&D and baker-consultant teams, to provide solutions that take these requirements into account.