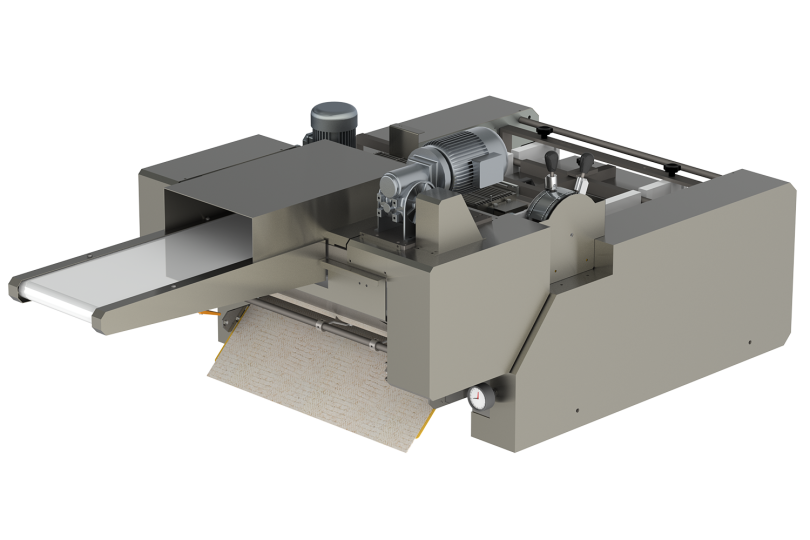

Armor I moulder

The horizontal moulder Armor I is similar in terms of operation and respect of the dough to those manufactured by MERAND from 1954, at the beginning of mechanical shaping in France. With its lengthen on a fixed table, it reproduces manual shaping and avoid dough heating up.

The 2-step lengthening will allow you to extend your baguettes to the desired length, without having to manually adjust them. The Armor I (for Industrial) can keep high daily rates thanks to its robust structure and mechanisms. Its fully-stainless steel casing and its thick sidewalls improve its life span, and are a guarantee of the factory settings upkeeping.

-

Up to 2 000 dough pieces per hour (depending on weight and dough type)

-

4 needle selectors for rolling and lengthening adjestments (more precise and faster than a clamping screw)

-

Guarantee of a very low level of sound in operation

-

2 lengthenings between the belt and the fixed table reproducing manual shaping

-

7mm thick felt for optimized shaping

-

Dough pieces weight - from 50g to 2 000g

-

Controls on the right side (possibility of having them on the left as an option)

-

12mm-thick aluminum flank to guarantee the maintenance of basic factory settings

-

Stainless steel casing

-

Reinforced sprockets in case-hardened steel for optimum durability

-

Stainless steel front feeding belt for a better entry of the dough pieces in the rolling system

-

Motorised flouring before the first lengthening to avoid dough sticking and improve final aspect of the shaped dough pieces

-

Calibrated upper lengthening for a better regularity, without tearing the dough

-

4 laminating rollers and one pre-rolling roller Alvéo+ to ensure good descent of the dough

-

Tradition pack including Alvéo+ and Pointop:

-

Alvéo+ lamination system: a roller with a honeycomb surface to prevent outgassing

-

Pointop: accessory for breads with pointed ends